Explore styles for your next wherever.

Time to travel.

Gear up for the new sunny season and miles that await.

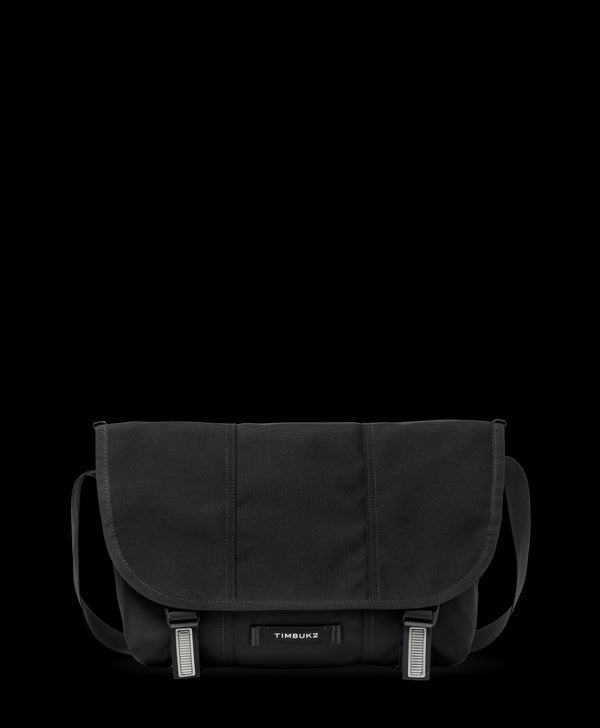

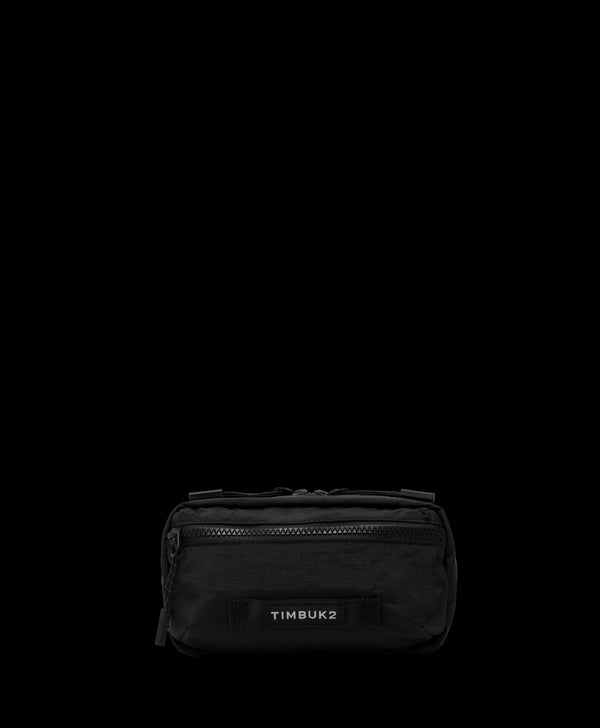

Hot Sellers.

Styles everyone's got to have.

Class or commute.

Find laptop bags made to keep tech safe on-the-go.

Laptop Backpacks

ShopInside Timbuk2.

Our story, stores, and more.